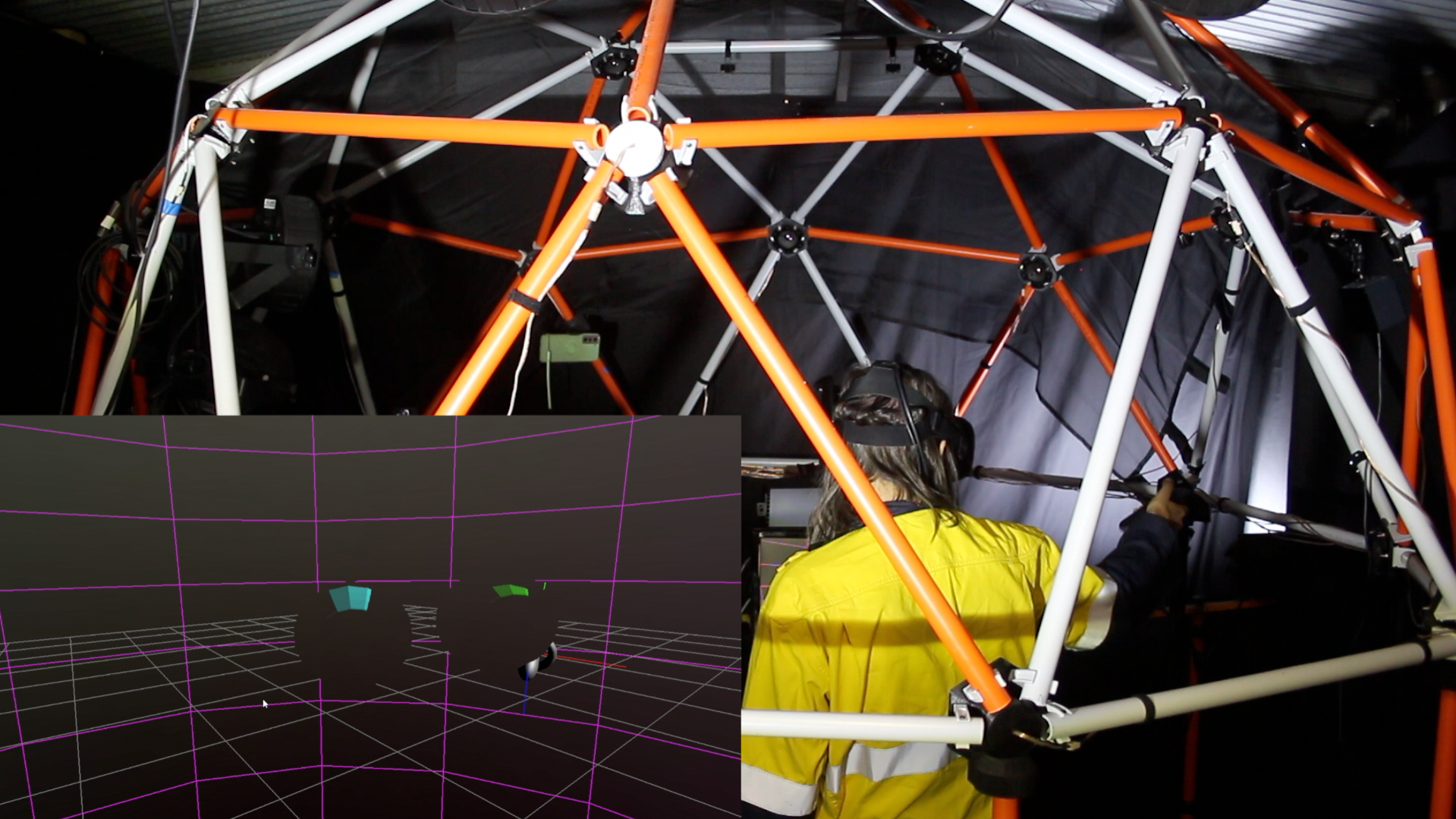

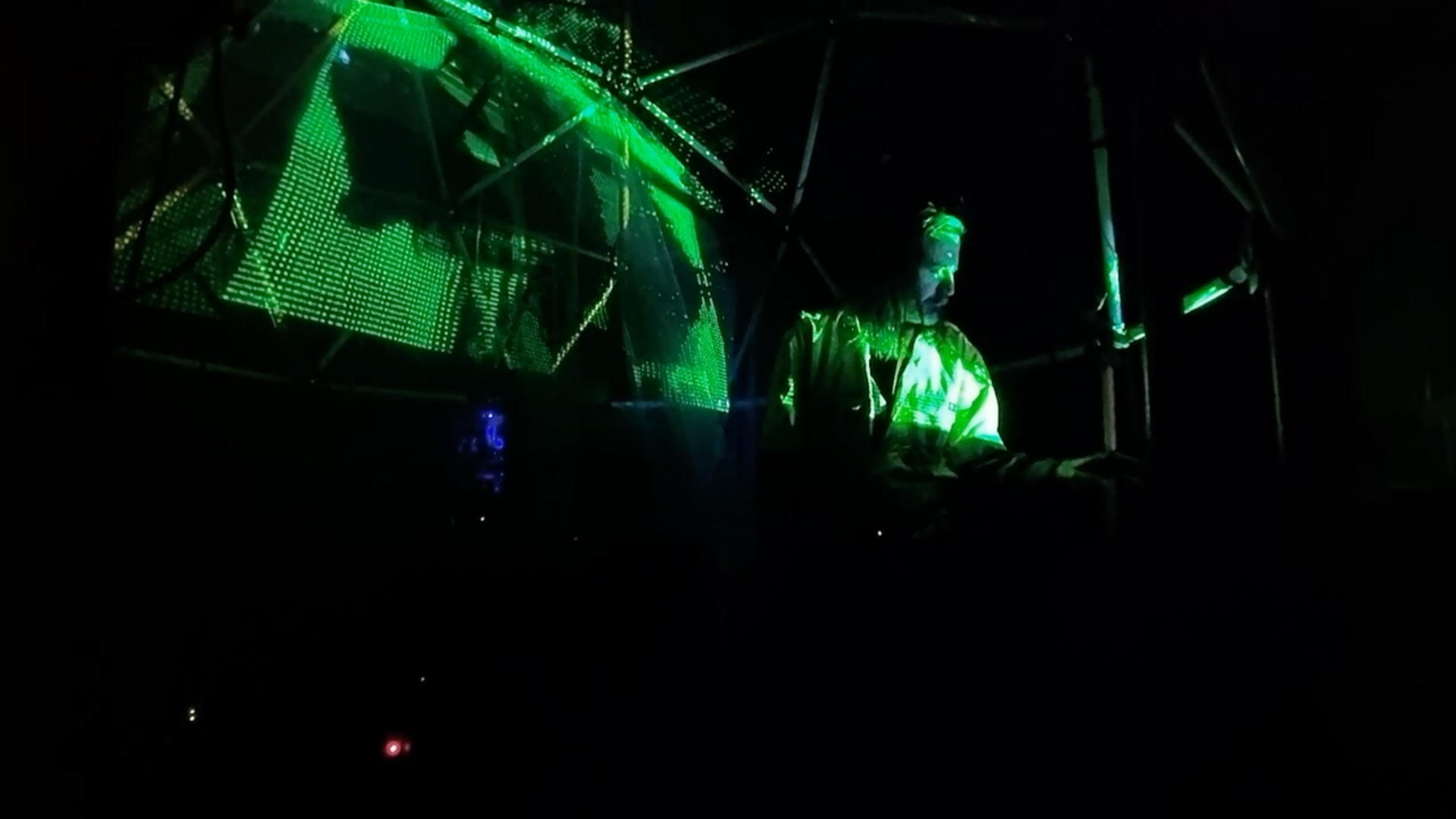

This small Ambisonic dome is, by design, a one-person experience. These works combine the immersion of Ambisonic audio with interactive augmented and virtual reality, creating very personal worlds that cannot be experienced through 2 dimensional media. Each work gives the audient different levels of agency, discovery and immersion. The VR headset views and projections are all generated in real-time with MAX. The audio content is a combination of Ambisonic processing in MAX, Cherry Voltage modular synthesiser and Native Instruments Reaktor.

Max/MSP, HTC Vive

Max/MSP, HTC Vive

Max/MSP, HTC Vive

Max/MSP, HTC Vive, Reaktor

Max/MSP, HTC VIVE, synthesizer, IMU sensor

Max/MSP, HTC VIVE, synthesizer, IMU sensor

Max/MSP, VIVE Tracker, synthesizer

These pieces were made to be experienced, not watched. Watching an immersive experience from the outside is like eating the menu at a restaurant – but below is a collection of short clips showing the system in action. ‘Coil’ and ‘Living Room’ use the Vive controller as an exploratory tool.

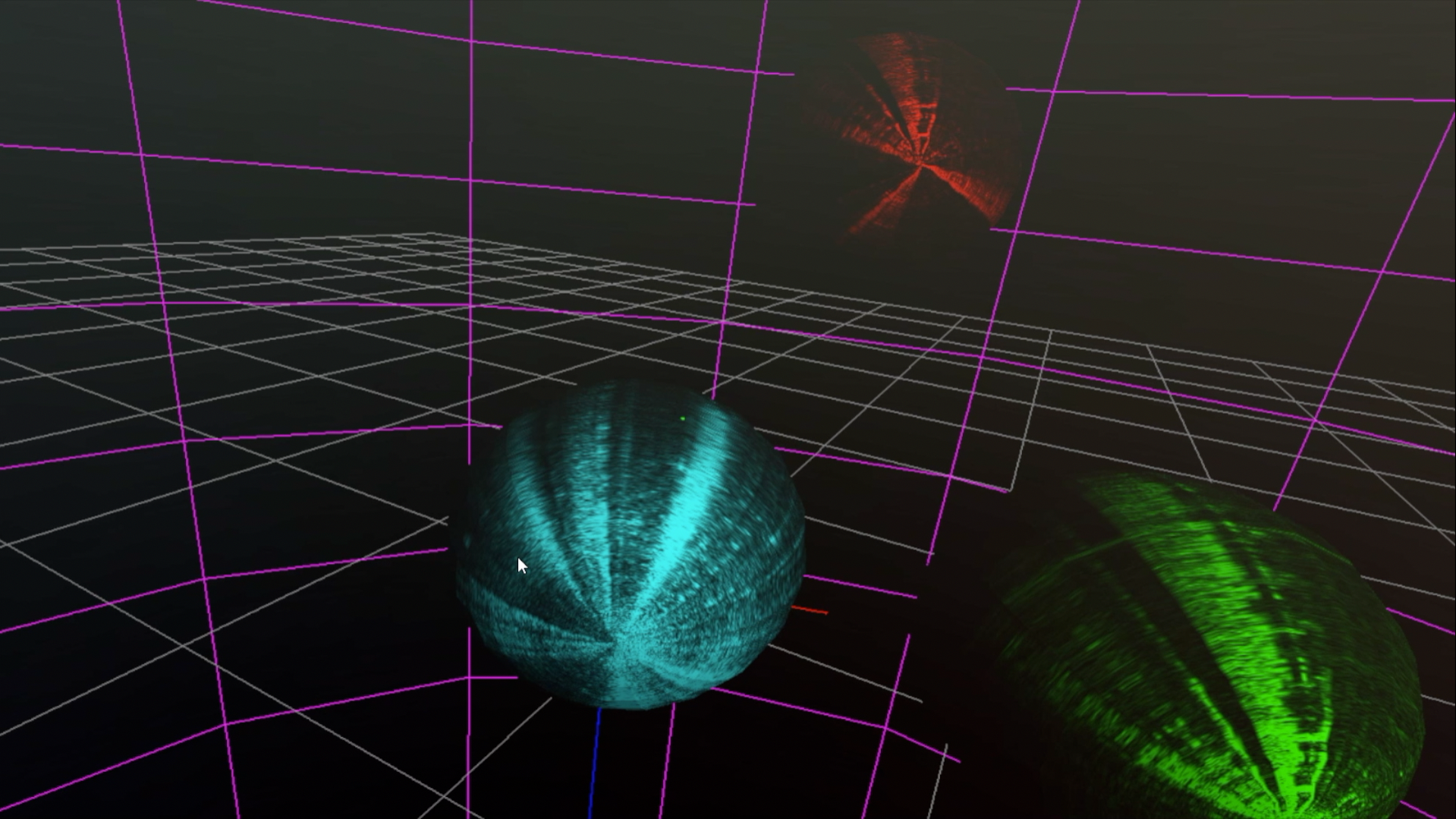

‘Coil’ places you inside a gradually intensifying map of the electromagnetic radiation emitted from consumer devices in a kitchen & lounge room. Discovering the unseen topology of the fields we live with every day is surprisingly visceral.

‘Living Room’ scales Australia down to 3 meters inside the dome. Dynamic maps of bushfire, rainfall and temperature variation can be selected via a bluetooth footswitch. Although you are inside the data projection, an FM modular synthesiser controlled by the position of the Vive handset is your only feedback, growing more discordant as time passes and the maps intensify. Areas without change are the only respite but they grow fewer and smaller as change accelerates.

‘Workspace’ is a subset of tools designed to make a complete VR mixing environment. The spherical audio emitters can be placed in 3 dimensional space, adjusted for volume and given animation paths that they will repeat until reset. Evaluating the efficacy of my DIY Ambisonic dome when combined with immersive headset VR in this manner was the subject of my thesis.

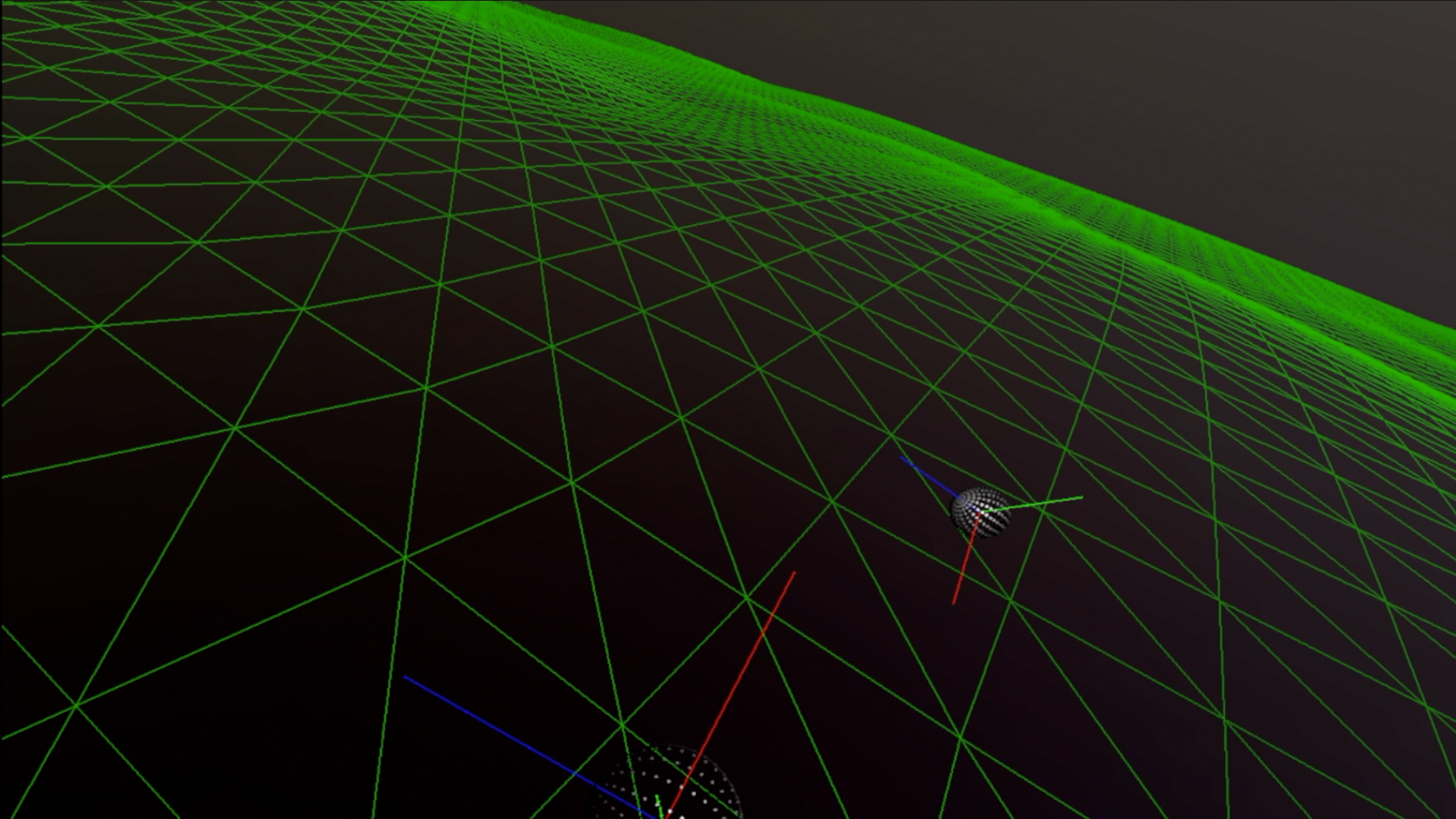

‘Drown’ is simple, largely passive and surprised me with the nasty intensity of the conveyed experience. This work is entirely dependent on the power of visual and audio VR immersion. Seated in the centre of the dome, over several meditative minutes your mind accepts the reality of the undulating wireframe ocean and drifting sound emitters. Then you realise that the level is rising. The moments when the water surface is just at head height and the waves are higher than you can crane your neck are genuinely disturbing.

A slightly redacted version of the artist statement can be downloaded here.